The software includes the following single pile capacity calculation methods:

1.AV method (Aoki & Velloso, 1975)

2.DQ method (Décourt & Quaresma, 1978 and Décourt 1996)

3.PFM method (Monteiro, 2000)

For all the above mentioned methods, pile bearing capacity (Q) for a closed ended pile is assumed to be the sum of :

Q = Qtip + Qshaft

Qtip = Atip × q

Qshaft = ∑ U ƒ dL

where:

Qtip: Pile tip resistance

Qshaft: Pile shaft resistance

q: Unit tip resistance

ƒ: Pile shaft unit friction

Atip: Pile tip area

U: Pile perimeter

L: Pile length

AV and PFM methods

Unit tip resistance q is calculated using the following formula:

q = k × N / F1

and shaft unit friction is calculated according to:

ƒ = α × k × N / F2

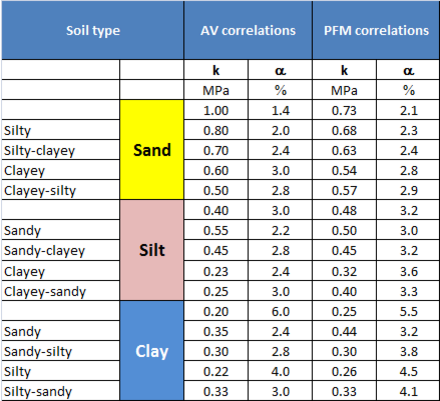

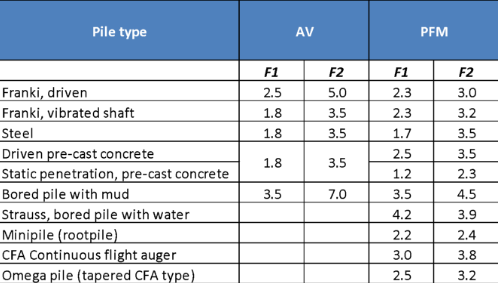

Values of k and α depend on soil and pile type. N is the uncorrected SPT value at a given depth of calculation. The following tables present the empirical coefficients for tip resistance q and shaft friction ƒ as a function of soil type.

DQ method

Unit tip resistance q is calculated using the following formula:

q = α × Κ × N

where the SPT value N at a given depth z is the mean value obtained at three depth levels: z-1, z and z+1. The average shaft unit friction is calculated according to:

ƒ = β × [(Nm/3) + 1]

where Nm at a given depth z is obtained from the SPT value at depth z-1. For this method the following limits apply:

•If N < 3 then consider N = 3

•If N > 50 the consider N = 50

The following tables present the empirical coefficients for tip resistance q and shaft friction ƒ as a function of soil type.

Limits to be considered

1. N values should not be greater than 50

2.The structural capacity of the pile (given value)

3.Micropiles in rocks may be analysed with N = 50 and it is recommended to consider shaft resistance only

4.Limits for micropiles unit values: q = 5 MPa, f = 250 kPa

5.Bored piles should limit the tip resistance calculated by these correlations. In general it is recommended that the pile tip resistance should be only 20% to the pile capacity. If the pile tip is cleaned with air-lift to remove soil cuttings or soil plug, this value can be raised to 35%